The Green Revolution in Material Handling: Why the Shift to Electric Forklifts and Stackers is Inevitable

The material handling industry is undergoing a seismic shift. For decades, the distinct rumble of diesel engines defined the soundscape of outdoor yards, while propane fumes were a necessary evil in many warehouses. However, with tightening emission regulations and the rapid maturation of battery technology, the "Green Revolution" is no longer just a buzzword—it is a business imperative. This article explores why businesses are migrating from internal combustion engines to electric solutions found in modern Three Point Forklifts and Full Electric Pallet Stackers.

The Decline of Diesel and the Rise of Electric

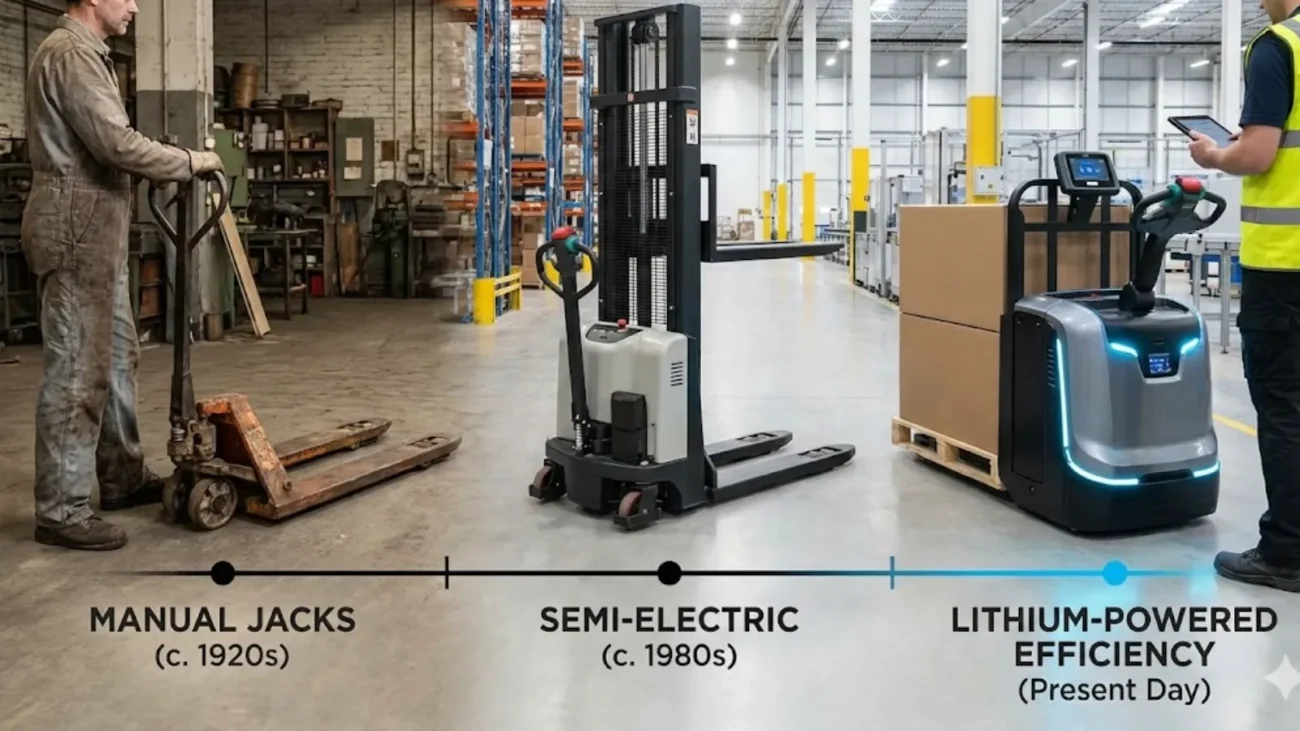

Traditionally, Electric/Diesel/GAS Forklifts were segregated by application. Diesel was for outdoor power; electric was for indoor air quality. Today, that line is blurring. Modern electric forklifts now rival their internal combustion counterparts in torque and lifting capacity. The driving force behind this is the Total Cost of Ownership (TCO). While the upfront cost of an electric unit might be higher, the elimination of fuel costs, fewer moving parts (no oil changes, spark plugs, or transmission fluid), and longer lifespans make them mathematically superior over a 5-year period.

The "NEW" Standard: Lithium-Ion vs. Lead Acid

Referring to the latest market trends, the "NEW" tag on Electric/Diesel/GAS Forklifts often points toward hybrid or advanced battery capabilities. The industry is moving away from heavy, maintenance-intensive lead-acid batteries toward Lithium-Ion. These batteries allow for "opportunity charging"—plugging the forklift in during a 15-minute break—which eliminates the need for battery swapping rooms and keeps Full Electric Pallet Stackers running across multi-shift operations without downtime.

Bridging the Gap: Semi vs. Full Electric

For small to medium enterprises (SMEs), the leap to full automation can be daunting. This is where the distinction between Semi Electric Pallet Stackers and Full Electric Pallet Stackers becomes critical.

Semi-Electric: Ideal for low-throughput warehouses. The lifting is powered, but the movement is manual. It reduces back strain without the cost of a fully motorized drive train.

Full Electric: The "NEW" industry standard for efficiency. With fully motorized lift and travel, these units maximize operator throughput and are essential for e-commerce fulfillment centers where speed is currency.

Conclusion

The transition to electric material handling equipment is not just about saving the planet; it is about saving the bottom line. By investing in modern Electric Forklifts and utilizing Full Electric Stackers, businesses can future-proof their operations against rising fuel costs and stricter environmental regulations.